From http://www.luminet.net/~bkuhl/building_tips.htm

Covering

A rather ingenious method is used for covering the AMA Cub / Delta Dart, the plan is the covering material. Build the plane on the covering material and then just cut around the edges and the covering is done. Although the plan covering material is very strong, it is also heavy and can warp severely under some conditions.

| Wrinkle Covering

Wrinkling the covering material by rolling it up into a ball and then flattening it out helps the warping problem greatly. The model may not look as neat, but will not warp easily.

|

|

Lighter Coverings

For a lighter covering, a material known as "Japanese Tissue" can be used. "Domestic tissue" is also available but would be heavier in weight. The question of what exactly is Japanese tissue came up on the Free Flight Mailing List recently. Many people had ideas, but this appears to be the correct answer:

Japanese tissue, in this case Esaki tissue, is made from a mixture of Ganpi (Gampi in English) and other materials. Esaki Model Co., think that pure ganpi tissue is weak, so they use a mixture. The chief material is Gampi.

Regards, Aki, Tokyo Japan

Cover the plan material with wax paper to use tissue covering. With Japanese tissue, put the glossy side down over the plans, and glue the balsa sticks to the tissue. You should still be able to see the plans through the tissue.

Correct Wing Position

|

|

|

From the directions for the AMA Cub, it would appear that the wing is directly behind the prop assembly. This is not correct, it would take a big lump of clay to balance the plane, something that should be avoided. Proper location will probably at 3/4" to 1" behind the front of the motor stick.

Improved Rear Hook

Rather than using a straight pin to fasten the rubber motor to at the rear of the plane, an improved rear hook can be made from a paper clip. With a longer loop of rubber, the loop can come loose when using a straight pin. The paper clip hook is made by cutting a paper clip and bending up one side at a 90 degree angle. Push the bent up section into the motor stick and glue. To make the hook even more secure, wrap thread around the hook and motor stick, then glue the thread.

Motor Stick Problems

| When using larger rubber widths such as 1/8”, there may not be sufficient clearance for the rubber knots to unwind resulting in the prop stopping in flight. One possible solution is to carve away material on the bottom side of the motor stick from where the plastic motor hangar ends to just ahead of the stab. This can also save a considerable amount of weight, just don't cut away too much. |

|

Getting the Dihedral Angle Right

One of the biggest problems that beginners have building the AMA Cub / Delta Dart, is gluing the wing to the motor stick with the proper dihedral angle. The instructions show a method where the plane is put upside down on the building board with the tip of the vertical fin and one tip of the prop touching the building board. the wing tips are then brought down to touch the building board. Although this method will work, this will result in more dihedral than is necessary.

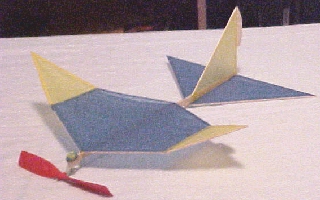

Too much dihedral will decrease performance, 1 1/2" dihedral at each wing tip should be sufficient. Not enough dihedral is not good either, especially outside. I know this having built a plane with not enough dihedral, it would do rolls in flight or spiral to the ground at times. My solution was to put some dihedral in the tips also, resulting in a polyhedral plane.

|

Polyhedral Delta Dart - result of not putting in enough dihedral in the wing to begin with. |

|

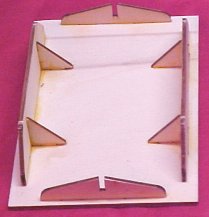

Wing Alignment Jig

The very easiest method of gluing the wing to the motor stick is with a jig such as the one sold by Midwest Products. Using laser-cut plywood pieces, the jig can be assembled very quickly.

|

| |

Midwest jig is easy to assemble from laser-cut plywood. |

The jig works well even with the competition's plane. |

Tips Sent by Chris Lenahan

Bill,

I enjoyed your website and have built a couple Cubs to learn about trimming using some of the modifications you suggested. I found an easy way to set the dihedral on the wing. I built a 1 1/2 inch support out of scrap balsa (basically a upside down "T") and placed the wing upside down centered on the support. I then took some scrap balsa (about 2 inches long) across the tips and pinned the scrap to my board (the support was also pinned to the board). This holds the wing at the required dihedral to be glued. I also cured my weak wing joint by taking a piece of scrap balsa (same as wing is constructed of) and sanded it to fit the gap. Leave the piece long so you have something to hold on to. Glue the scrap into the gap and once it is dry trim and sand the piece flat. Since doing this I have had no problem with the wing folding.

The AMA Cub is a great beginners model, easy to build and it flies well. I had one go OOS, had to get in the truck and chase it. Found it a couple blocks away.